With fully staffed Advanced Applications, Software Integration, Engineering, and Build teams, we aim to be the certified international market player in the design, distribution and implementation of industrial automation solutions

TRUC QUAN Robotic bag palletizing solution is provided to meet the most rigorous demands of pallet patterns, stability, precision and cycle time for your palletizing needs.

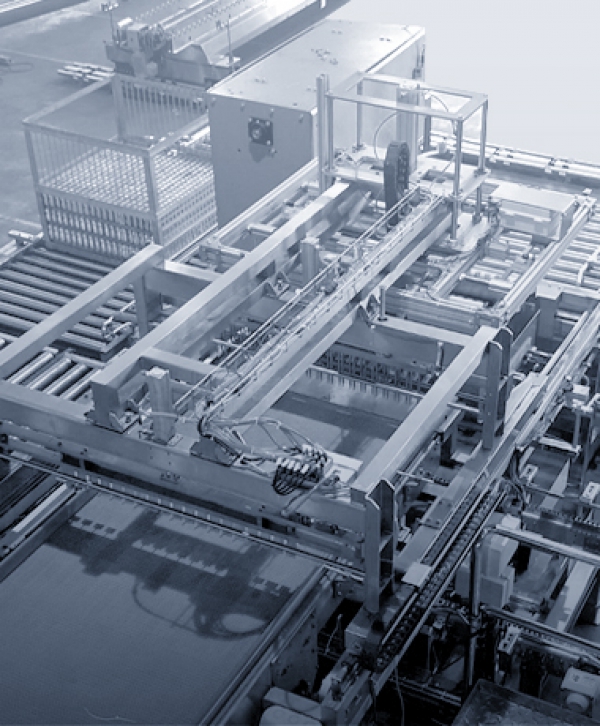

Robotic Palletiser Systems are the most flexible method of automated product handling, being able to palletize a diverse range of applications with less product damage than manual handling in continuous motion and offering speed of up to 2200 cycles per hour.

We know that it is vital to deliver to our customers the systems which not only are stability and flexibility but also cost – effective. That’s the reason why our well – trained engineers have committed to develop a solutions of the most innovative technology with a space – efficient footprint. Moreover, Robotic Bag Palletising is integrated with simple control platform and a variety of gripper attachments while using the top quality components from trustworthy suppliers, such as Rockwell, Sumitomo and Festo …

We are utilizing the state-of-the-art ABB Robot to our robotic systems which have the latest technology. Our partnership shares a common purpose in providing our customers the quality robotic systems and outstanding support packages. In additions, TRUC QUAN’s area of expertise in conveyor systems and highly – specialized in automation allow us to provide our customers a bespoke and job - specific solution. Depend on the project, we can offer standard or custom - designed machinery, combining with appropriate equipments to meet any specifications.

A significant element of Truc Quan solutions is the PLC control with HMI (Human Machine Interface), which allow the operator to execute tasks in a clear, easy-to-use menu. Our engineers have customized the software to make it even more user - friendly when change over between various products or pallet patterns.

Here at Truc Quan we always maintain the availability of spare parts and an excellent after sales service, as it is crucial to minimizing manufacture downtime. Our highly skilled teams thorough installation, training and support ensure the smoothly operation as well as immediately response if a problem or unplanned downtime happens, especially in local projects.

FEATURES

OPTIONS

AUXILIARY MECHANICAL EQUIPMENT

| SPECIFICATIONS | |

| Dimension | 15000 x 9800 x 1200 |

| Pay load | 2500 Kg |

| Power consumption | 3 Phases, 400 V – 50 Hz |

| Air requirement | 6 bar |

| Ambient temperature | +5°C to +40°C |

| Noise level | < 75 dB |