With fully staffed Advanced Applications, Software Integration, Engineering, and Build teams, we aim to be the certified international market player in the design, distribution and implementation of industrial automation solutions

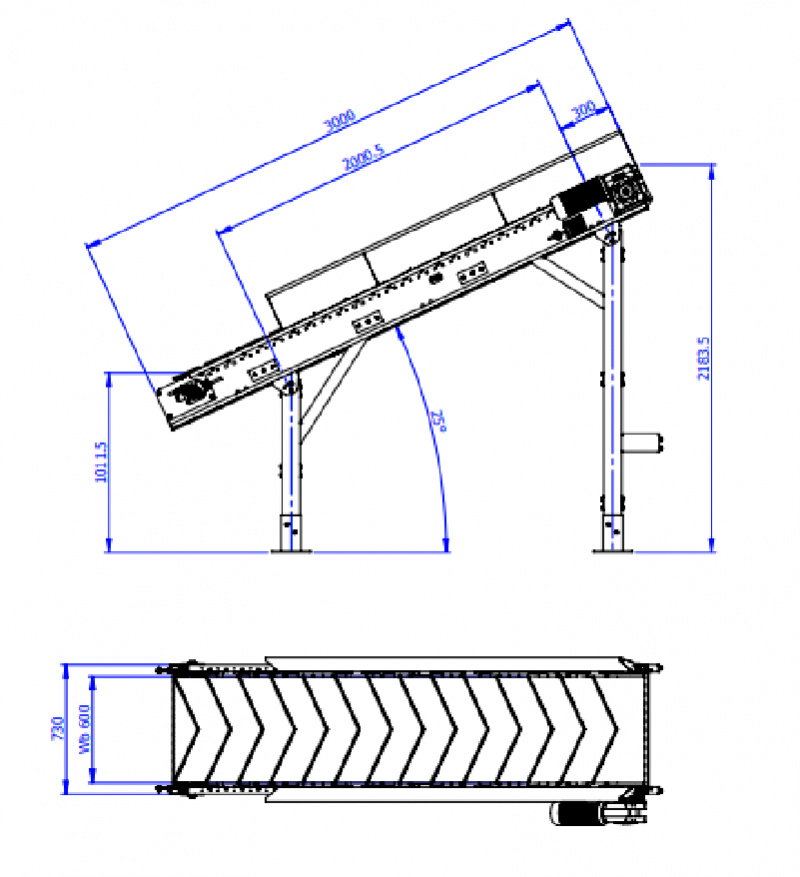

A bag conveyor is a specialized material handling system designed to efficiently transport bags or packaged goods between different levels or locations, ideal for warehouses, loading docks, and production facilities. These conveyors are equipped with durable rubber belts, typically 8-10mm thick, supported by a robust, powder-coated steel frame, ensuring long-term durability under heavy loads.

The conveyor can connect seamlessly with telescopic conveyors for loading and unloading trucks or containers, streamlining the transfer process and minimizing manual handling, which reduces labor costs and risk of injury. Adjustable height settings enable flexible usage across various elevations, making it adaptable to diverse operational requirements.

Its control system includes a waterproof IP65-rated control cabinet, speed adjustment via inverter, and safety features like emergency stop buttons placed at strategic locations. Optional accessories include a collection chute beneath the belt, customizable paint colors, and mobile wheels, enhancing functionality and adaptability to specific operational needs.

FEATURES

CONTROL

OPTIONS

| SPECIFICATIONS | |

| Size | 3000 x 730 x 2183 |

| Speed | 30 m/p |

| Loading capacity | 50 Kg/m |

| Direction | Reversible |

| Frame | Steel SS400, powder painted |

| Rollers | Steel |

| Belt | Rubber, T:6mm, Color: Black |

| Power supply | 3 phases, 380 V, 50 Hz + N + PE |